Fix Self Propelled Lawn Mower

Mower engine runs fine but it won’t pull itself anymore? Before you panic about needing a new transmission, check the drive cable. That’s the problem 80% of the time and it’s a free fix - just turn a little barrel adjuster. If that’s not it, keep reading.

Table of Contents

- Drive System Types

- Quick Diagnosis

- Cable Adjustment

- Belt Replacement

- Transmission Issues

- Wheel and Gear Problems

Drive System Types

Front Wheel Drive (FWD)

- Drive wheels in front

- Better for flat terrain

- Lighter front end

- Common on basic models

Rear Wheel Drive (RWD)

- Drive wheels in back

- Better traction (weight over wheels)

- Better for hills

- Most common type

All Wheel Drive (AWD)

- All four wheels powered

- Best traction

- More complex

- Higher maintenance

[NEED IMAGE: Self-propelled drive system types comparison]

Quick Diagnosis

Diagnostic Flowchart

Self-propel not working

│

├── Bail lever feels normal?

│ ├── YES → Check cable at transmission

│ └── NO → Cable disconnected at handle

│

├── Cable tight at transmission?

│ ├── YES → Check belt condition

│ └── NO → Adjust or replace cable

│

├── Belt intact and tight?

│ ├── YES → Transmission or wheel issue

│ └── NO → Replace belt

│

└── Wheels turn freely by hand?

├── YES → Internal wheel gear issue

└── NO → Debris or bearing issue

Quick Checks

- Cable connection - Connected at both ends?

- Cable tension - Slack in cable?

- Belt condition - Visible without removing covers?

- Wheel engagement - Do wheels resist turning when bail engaged?

Cable Adjustment

When to Adjust

- Weak or intermittent propulsion

- Bail travels far before engaging

- Recently replaced cable

- Seasonal tune-up

Adjustment Procedure

Location: Cable adjuster is at the transmission (rear of mower) or at the handle (some models)

Steps:

- Locate adjustment barrel

- Loosen jam nut (if present)

- Turn barrel clockwise to tighten

- Test engagement

- Repeat until smooth engagement at mid-travel

- Tighten jam nut

[NEED IMAGE: Self-propelled cable adjustment location]

Proper Adjustment

- Too loose: Bail goes to handle before engaging

- Too tight: Drags or engages immediately

- Just right: Smooth engagement at mid-travel, slight slack when released

Cable Replacement

When cable adjustment runs out:

- Purchase correct replacement cable

- Disconnect at both ends

- Note routing through guides

- Remove old cable

- Route new cable same path

- Connect at transmission first

- Connect at handle

- Adjust tension

Cable cost: $15-30 depending on brand

Belt Replacement

Symptoms of Bad Belt

- Slipping (squealing)

- No propulsion with tight cable

- Visible cracks or glazing

- Belt came off

Belt Access

Most mowers:

- Tip mower back (air filter up)

- Remove blade for access

- Belt is visible around transmission pulley

Some models require:

- Removing rear cover

- Dropping transmission

- Partial disassembly

[NEED IMAGE: Self-propelled drive belt location]

Belt Replacement Steps

- Disconnect spark plug

- Tip mower back

- Remove blade (for access)

- Note belt routing

- Release tensioner

- Remove old belt

- Install new belt on pulleys

- Re-tension

- Reinstall blade

- Test operation

Belt Part Numbers by Brand

| Brand | Common Models | Belt Number |

|---|---|---|

| Toro | Recycler | 117-1018 |

| Honda | HRX/HRR | 22431-VL0-B01 |

| Craftsman | M-series | 954-04259 |

| Husqvarna | LC series | 532197253 |

Transmission Issues

Symptoms of Transmission Failure

- Cable tight, belt good, still no propel

- Grinding noise from transmission

- Intermittent propulsion

- Transmission pulley spins but wheels don’t

Transmission Types

Variable speed (most common):

- Internal mechanism varies output

- Responds to cable input

- Not rebuildable - replace entire unit

Fixed speed:

- Simple on/off engagement

- Often belt-clutch type

- May be rebuildable

Transmission Replacement

Steps:

- Remove belt from transmission

- Disconnect cable

- Remove mounting bolts

- Note axle/gear alignment

- Remove transmission

- Transfer pulley to new unit (if needed)

- Install new transmission

- Reconnect cable and belt

- Adjust cable tension

Transmission cost: $60-150 depending on brand

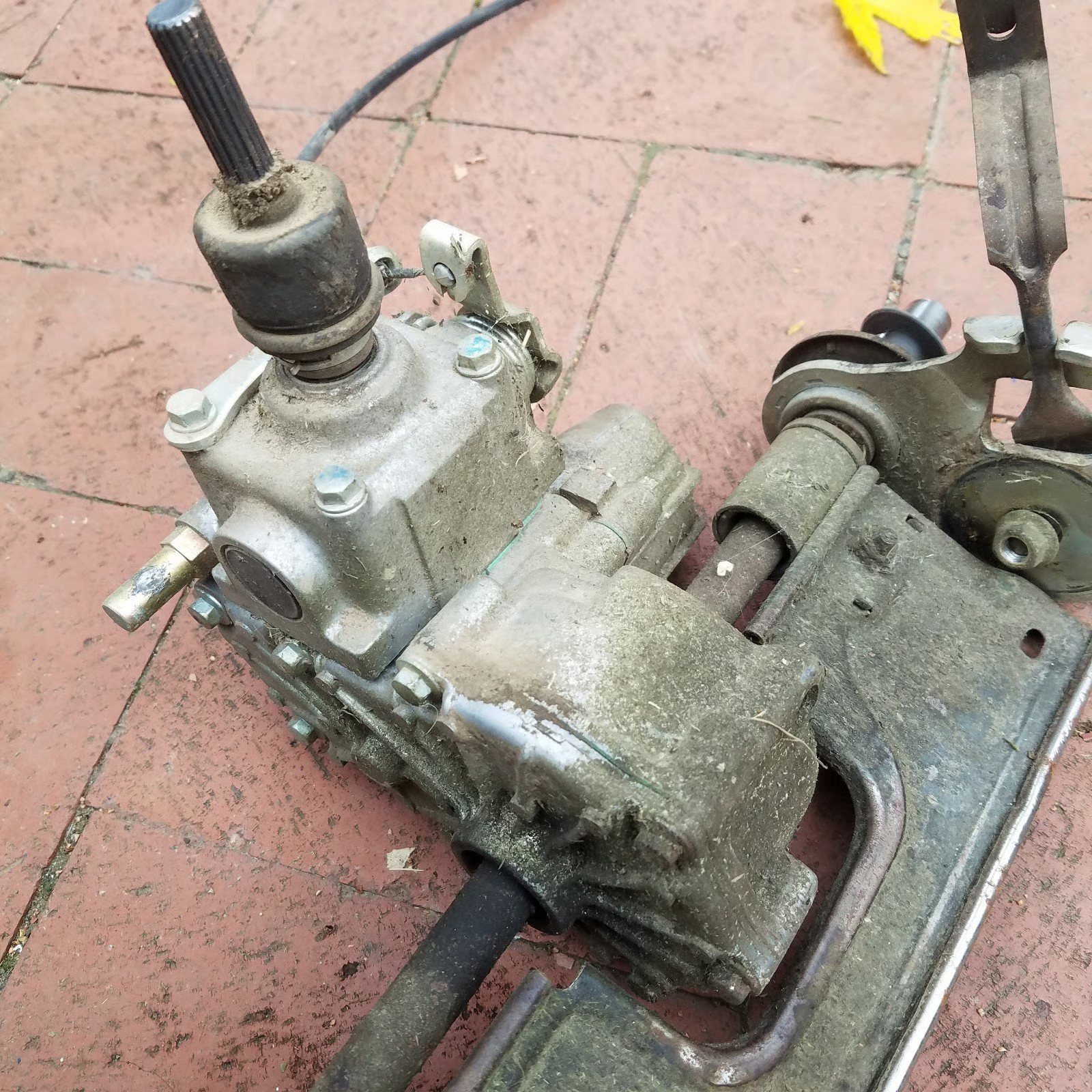

[NEED IMAGE: Self-propelled transmission replacement]

Wheel and Gear Problems

Internal Wheel Gears

Many self-propelled mowers have drive gears inside the rear wheels.

Symptoms of worn wheel gears:

- Clicking noise when propelling

- One wheel doesn’t drive

- Wheel slips on axle

Fix: Replace wheel assembly (gears not sold separately on most models)

Wheel cost: $30-60 each

Axle Issues

Bent axle symptoms:

- Wobbling wheel

- Uneven drive

- Grinding noise

Fix: Replace axle or entire transmission assembly

Debris and Buildup

Grass and debris can jam drive components.

Check:

- Inside wheel hub

- Around axle

- Between belt and pulley

- Inside transmission pulley groove

Brand-Specific Tips

Toro Personal Pace

- Variable speed responds to handle pressure

- Cable adjustment is critical

- Transmission is expensive but reliable

- See Toro Personal Pace Parts

Honda Smart Drive

- Variable speed controlled by lever

- Uses different cable setup

- Very reliable transmission

- Check drive clutch if issues

Craftsman/MTD

- Often uses simple belt-clutch

- Belt tension is critical

- Cheaper transmission replacement

- Check for MTD parts compatibility

Repair Costs

| Repair | DIY Cost | Shop Cost |

|---|---|---|

| Cable adjustment | Free | $25-50 |

| Cable replacement | $15-30 | $50-100 |

| Belt replacement | $15-30 | $75-125 |

| Transmission | $60-150 | $150-300 |

| Wheel (each) | $30-60 | $60-100 |

Prevention

Extend Drive System Life

- Don’t force mower through thick grass

- Avoid hitting obstacles

- Keep belt and pulleys clean

- Lubricate cable annually

- Adjust cable as needed

Storage

- Release cable tension

- Clean drive components

- Store indoors

Related Guides

- Toro Personal Pace Parts Diagram

- Lawn Mower Belt Replacement

- Honda HRX217 Problems

- Craftsman Lawn Mower Parts

Summary

Most self-propelled problems are cable-related. Start with adjustment - it’s free and fixes 70% of issues. Belt replacement is the next most common repair. Transmission failure is less common but requires replacement (not rebuildable). Keep the drive system clean and properly adjusted for longest life.